Carmakers accelerate efforts to build ventilators, masks as coronavirus crisis deepens

Ford and others have stepped up efforts to fight the global pandemic.

Ford Motor Co. on Tuesday said it was partnering with 3M and GE Healthcare to speed up production of medical equipment and supplies for health care workers on the front lines of the coronavirus pandemic.

The Dearborn, Michigan, automaker, working closely with GE, will manufacture a simplified version of GE's existing ventilator design. These ventilators, which deliver air to COVID-19 patients in respiratory distress, could be produced at a Ford manufacturing site in addition to a GE location.

"We have a range of options in terms of facilities that we can leverage to build these things," Jim Baumbick, vice president of enterprise product and line management at Ford, told reporters Tuesday on a conference call. "We are expanding their capacity and leveraging what GE Healthcare and 3M have."

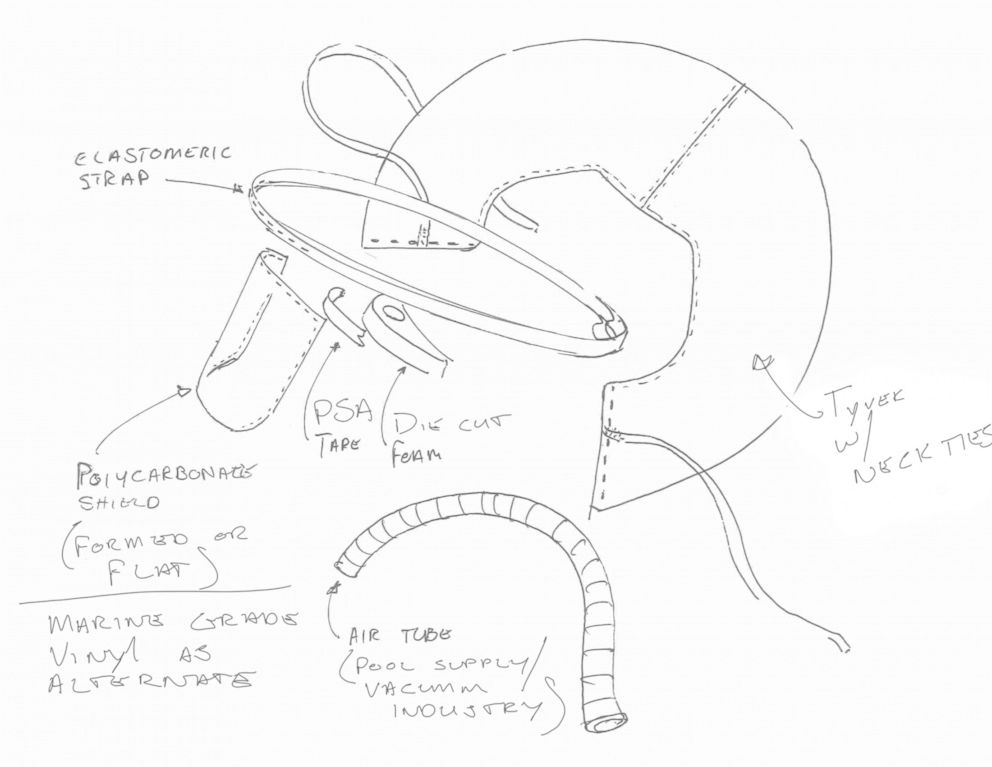

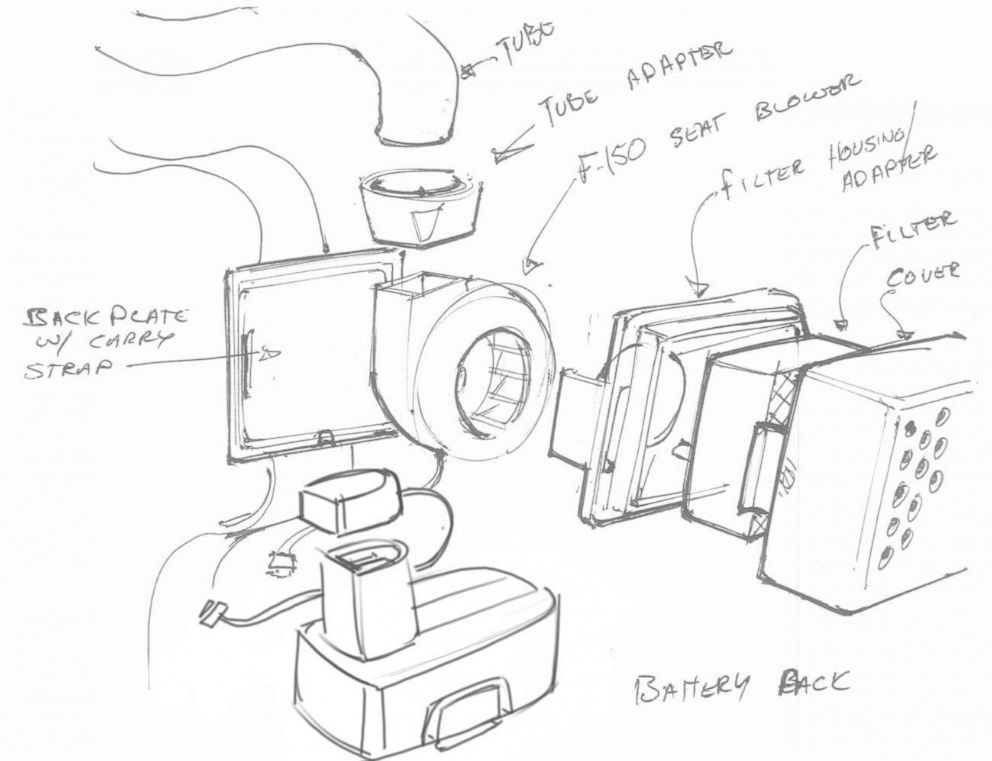

Ford engineers are also helping to boost manufacturing capacity of 3M's Powered Air-Purifying Respirators (PAPRs) by wielding parts from both companies to quickly get respirators to hospitals and health clinics. Off-the-shelf parts include fans from Ford F-150's cooled seats and portable tool battery packs that can power respirators for up to eight hours. Mike Kesti, global technical director at 3M's personal safety division, said the goal was to increase production tenfold from current levels.

"We're really impressed with Ford's response," Kesti said on the call. "We are trying to be creative, agile and resourceful ... focusing on increasing scale and impact."

Moreover, Ford said its workers, in cooperation with the UAW, would assemble more than 100,000 plastic face shields per week at a Ford manufacturing facility and apply its in-house 3D printing capability to produce disposable respirators.

The coronavirus pandemic has sickened more than 392,000 people around the globe and at least 17,159 have died since the first case was reported last December in Wuhan, China. Health officials and hospitals worldwide have pleaded with private businesses and world leaders to ramp up production of lifesaving medical devices.

President Donald Trump tweeted Sunday that he had given U.S. automakers the "go ahead" to manufacture ventilators and "other metal products, FAST."

General Motors and Fiat Chrysler Automobiles (FCA) have also stepped up efforts to alleviate the dire shortage of medical devices across America.

FCA said it would manufacture and donate more than 1 million protective face masks per month to police, EMTs and firefighters as well as workers in hospitals and health care clinics. FCA will start manufacturing the masks in the coming weeks with initial distribution across the United States, Canada and Mexico.

GM said it would work with Ventec Life Systems "to enable Ventec to increase production of its respiratory care products to support the growing fight against the COVID-19 pandemic," adding that Ventec will "leverage GM’s logistics, purchasing and manufacturing expertise to build more of their critically important ventilators."

Carla Bailo, president and CEO of the Center for Automotive Research, said she would like to see more collaboration among automakers to stop the virus' insidious spread.

"Everyone needs to protect the health of the country ... it's what we should be doing," she told ABC News. "These companies can't build cars now so let's form partnerships and work together."

Retooling a car assembly line and turning it into a "ventilator line" may be unrealistic, she noted, but carmakers could set up temporary tents to manufacture the devices. Automakers would have to establish safety protocols to make sure the workers coming back to the production line are healthy and provided with the appropriate masks, shields and other equipment needed to perform the job with zero risk of infection.

"But the key is getting the parts and components and quickly enabling training," she added.

Dan Hearsch, a managing director in the automotive and industrial practice at consulting firm AlixPartners, applauded automakers for proactively taking action.

"This is a big deal," he told ABC News. "They're lending their supply chain and manufacturing expertise to other industries. [It's about] how do you get the most out of production quickly and efficiently."

Tesla CEO Elon Musk, who has questioned the reported danger of the coronavirus, changed course on Sunday, tweeting that Tesla and SpaceX, his private space transportation services company, would distribute 1,255 ventilators from China this week but "getting them delivered, installed & operating is the harder part."

He also noted that members of his team have been in talks with Medtronic about the production of ventilators.